This is no different when discussing trends for MCAD tools in Silicon Valley. This undercuts the other two competitors by several thousands of dollars, although in recent years the competition has lowered their entry price to be competitive.īut like the eccentric trends it is known for, Silicon Valley marches to the beat of its own drum and is fickle, and thus what the rest of industry nationally aspires to is rejected for new and different ways of working. Since its introduction, it has disrupted the market–not only for it’s ease-of-use, but the price point and overall cost of ownership starting at a base price of $3995. Introduced in 1995, SolidWorks has grown the fastest over the last two decades and has more in-use “seats” worldwide being used in a wide variety of product design industries. It differentiates itself from CREO and NX on ease-of-use and integration with the Windows OS. Yet, unlike software product development, consumer product development requires, arguably, many more disciplines (including software) to bring a product to market.

In addition to creating 3D assets, ID’s also create compelling photorealistic 3D illustrations using additional visualization software like Keyshot, Photoview, Visualize, Maxwell Render, Modo, Vray, and 3dmax, some of which are plug-ins to the aforementioned MCAD products.

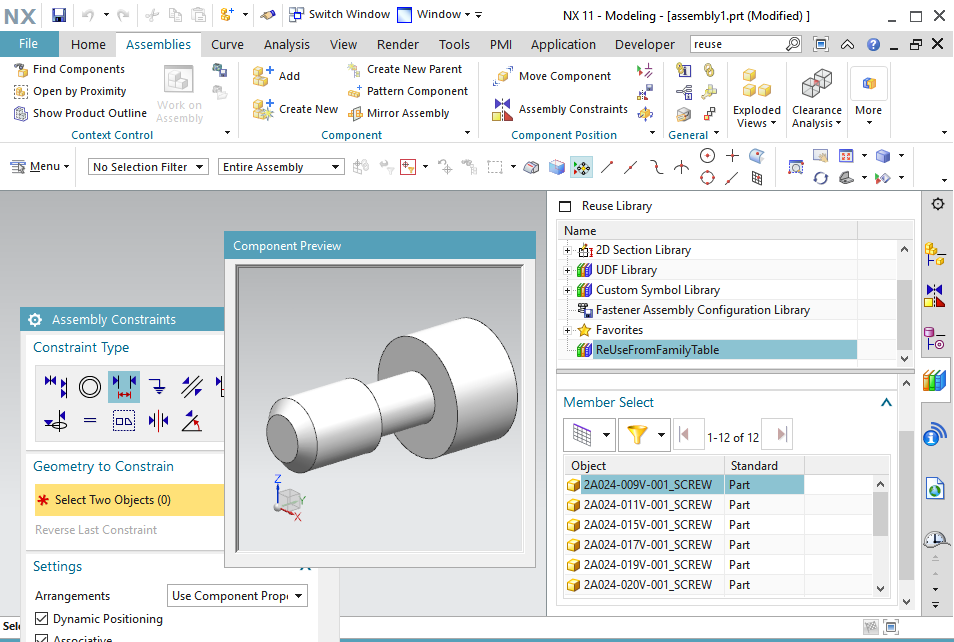

For ID’s, the tools of choice are Alias, an Autodesk product, Rhino and SolidWorks. For Industrial Designers who conceptualize the form, ergonomics and user experience, a more select class of modeling and visualization tools is used.Ĭurrently, the “big three” MCAD tools of choice in Silicon Valley are SolidWorks, a subsidiary of Dassault Systems CREO from PTC (formerly known as ProEngineer) and NX (formally known as Unigraphics) a division of Siemens. Software tools for Mechanical engineers and Industrial designers consist of MCAD (Mechanical Computer-Aided Design) along with PDM (Product Data Management) and, in some cases, FEA (Finite Element Analysis) for virtualizing material strength, heat flow, etc. Yet with the transition from software to hardware, these companies are presented with new and unfamiliar challenges: longer development lead times and capital investment in tooling and parts inventory, and mechanical engineering software tools. Silicon Valley, best known as a mecca for software and semiconductor development for decades, has also attracted much hardware development lately with mega software giants, Google, Facebook, Microsoft, and Amazon developing their own consumer electronics.

0 kommentar(er)

0 kommentar(er)